- Olive Oil Chemistry Definitions and Standards

- Can I Cook With Extra Virgin Olive Oil

- Confusion About Fusion vs. Infusion

- What is Balsamic Vinegar

- Nutritional Information

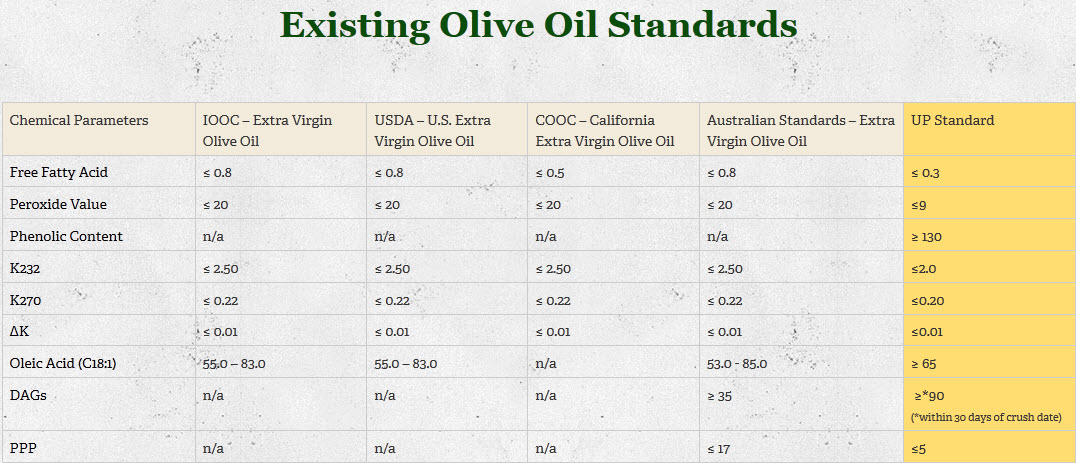

OLIVE OIL STANDARDS

Fresh crushed olive oil is like fresh squeezed fruit juice in that it contains the most flavor and nutrients, and is best consumed when it is freshest. Old, poorly made, and improperly stored extra virgin olive oil yields fewer, if any, health benefits and less desirable flavor.

All of our fresh fruit olive oils are certified ULTRA PREMIUM (UP) extra virgin. Ultra Premium is the highest quality standard, exceeding all current world standards – it means we have the freshest and finest EVOO in the world. We source from hand selected growers who meet our criteria for picking methods and timing, time to crush, and time to store. Learn more about the Ultra Premium Standard.

OLIVE OIL CHEMISTRY DEFINITIONS

Becoming intimately familiar with a particular extra virgin olive oil’s flavor characteristics and chemistry i.e. antioxidant content, oleic acid, and FFA will help you make an educated decision about which olive oil is right for you.

Oleic Acid:

- The major monounsaturated fatty acid found in olive oil

- Olive oil is generally higher in oleic acid than other vegetable fats

- The range found in extra virgin olive oil is between 55-85%

- A higher oleic acid monounsaturated fat content translates into increased durability and shelf-life because the oil has a greater resistance to oxidation

FFA:

- Fatty acids are “free” when they are not bound to any other molecule. FFA are formed by the breakdown of triacylglycerols during extraction

- A low FFA is desirable

- FFA speaks to the condition of the fruit at the time of the crush

- The higher the FFA, the greater the indication of poor quality fruit such as damaged , overripe, insect infestation, overheating during production or too much delay between harvest and crush

Peroxide Value:

- Peroxides are the by-products of the oxidation

- Peroxides are formed when the FFA in the oil is exposed to oxygen causing defective flavors and odors

- A very low peroxide value is desirable

Polyphenol Count:

- Phenols are healthful antioxidant substances found in olive oil which aid in slowing down the natural oxidative process

- Phenolic content decreases over time or when exposed to heat and light, and is an indicator of freshness, with higher amounts improving shelf-life and oxidative stability

- Polyphenols such as Oleuropein, Oleocanthal, and hydroxytyrosol impart intensity connected with pepper, bitterness and other desirable flavor characteristics

Diacylglycerols (DAGs):

- Diacylglycerols are formed as triacylglycerols breakdown

- Fresh olive oil has a much higher proportion of 1,2-diacylglycerols to Total diacylglycerols

- Elevated ratio of 1,3-diacylglycerols are an indication of olive oil extracted from poor quality fruit or of refined oil

Ultraviolet (UV) Light Absorption:

- K232, K270, ΔK are all UV Spectrophotometric determination of rancidity in oil

- Elevated levels of UV absorption indicate oxidized and/or poor quality oil, possible refining and/or adulteration with refined oil

PPP:

- During the degradation of olive oil, chlorophyll pigments breakdown to pheophytins and then to pyropheophytins

- The ratio of the two is useful in distinguishing fresh olive oil from refined oil

CAN I COOK WITH EXTRA VIRGIN OLIVE OIL

“Is it OK to heat up extra virgin olive oil and cook with it?” This is a complicated question. Supermarket olive oil, labeled as “extra virgin olive oil”, which is not adulterated with refined oil, but is of a typical poor quality as a result of lax processing standards, age, UV light exposure, and poor handling tends to be highly oxidized and or rancid by the time the consumer purchases it. Highly oxidized or rancid olive oil lacks the protective chemistry that would otherwise allow for abuse at higher temperatures before reaching the smoke point.

CONFUSION ABOUT FUSION VS. INFUSION

There is some confusion surrounding the terms fused and infused, which are the two different processes used to flavor extra virgin olive oils.

First, lets talk about “fused” olive oil or what is also referred to as “agrumato” in Italy. Agrumato olive oil is made by crushing ripe, sound olives with whole, fresh fruits, herbs or vegetables at the time of crush. In the winter, at our mill in Tunisia, citrus fruit is picked at the peak of ripeness, split in half and then thrown in with the olives. The olives and fruit are then crushed simultaneously. This process allows for the essential oils from the citrus peel to mingle with the oil from the olives. By the way, ripe olives contain up to 20% oil but the majority of an olive is comprised of water. The waste water from the citrus and olives are centrifuged away and the result is a bright, fresh, fused citrus olive oil.

More than 90% of the world’s fused or agrumato olive oil is made in the Northern Hemisphere. Because agrumato is typically made from ripe olives at the end of the season, the window for crushing in the Northern Hemisphere is in the winter, usually between mid December and late January. With few exceptions, many fresh fruits, vegetables and herbs are unavailable during these cold winter months. More often than not, when one sees a product claiming that it is an agrumato chili oil or agrumato basil oil, the mill is either adding frozen or freeze dried product to the olives at the time of crush, or simply misrepresenting the process and actually infusing olive oil after the fact.

“Infusion” is the process of adding flavor to olive oil after it has been made. For some, infusing olive oil is nothing more than attempt to cover up poor quality, defective, old oil. The problem with this strategy is that regardless of what flavoring is added to poor quality olive oil to mask it, the rancidity, fustiness and other negative attributes will still be evident underneath. Furthermore, synthetic chemicals and flavors are often implemented as flavoring agents because they are more cost effective than, say, essential oils, concentrates or extracts. This “garbage in, garbage out” mentality is rampant in the industry where aesthetics and health take a backseat to the bottom line.

In the test kitchen, when formulating our infused extra virgin olive oils, we have a simple mandate to adhere to. The infused extra virgin olive oils that we make will use the freshest extra virgin olive oils available in our collection that are most aesthetically compatible with the natural products we use to flavor them with. This simple mandate requires that the chemistry, freshness and quality of our infused olive oil are second to none. We are not in the business of flavoring a single oil from a single hemisphere. We painstakingly move our infused collection to coincide with the fresh crush. It is a labor of love that we hope you find evident in the flavor, freshness and quality of our products.

OUR BALSAMIC VINEGAR (CONDIMENTO) FROM MODENA, ITALY

We refer to our dark balsamic as “Traditional Style Condimento, Aged Up to 18 Years”. Our dark condimento is of the highest quality and is made in Modena, Italy from cooked, high quality caramelized grape must from Trebbiano and Lambrusco grapes. The grape must in our Condimento is cooked over an open wood fire, just as DOP Traditional Balsamic grape must is. It is cooked down to the same consistency, density and dry solid extracts, actually. DOP Traditional Balsamic dictates that wood-fire-cooked grape must is then put directly in to old, fired wood barrels which were used to age balsamic in years past. These barrels become progressively smaller as the product becomes thicker and naturally evaporates over time. The barrels as well as the product they once contained, add character to the must over time. Nothing is ever added to the cooked, caramelized must of DOP balsamic. Pro-biotic wild yeast and acetic bacteria colonize it and eventually raise the acidity. It slowly ages in this manner and turns in to “vinegar” by itself over the course of many years, hence the scarcity and price tag.

By Italian law, DOP balsamic must then undergo strenuous sensory evaluation as well as laboratory analysis which measures extensive criteria including and most importantly, dry extract solids. Once approved as DOP, it can then only be sold in 100 ml. bottles which are identical based on two exclusive regions of production, Emilio Reggiano or Modena Italy. The bottles from each region are uniform in size and shape regardless of who produced the balsamic. The consortium then licenses the producer to use the 100 ml. DOP bottle which is then, wax sealed, numbered and boxed for individual sale. The wax sealed numbered bottles will never be sold unboxed, as a loose bottle by itself. Furthermore , it is never, sold in other types of bottles outside of the 100ml. DOP bottle, and certainly never in bulk, EVER! Furthermore, this product is rarely, if ever, used for cooking. It is far too prized and expensive. For this reason, it’s typically served drop by drop on a spoon, like a digestif after a meal. We urge you to open a tiny wax sealed and numbered bottle of DOP balsamic and compare it with our Traditional Style Balsamic Condimento of Modena, Italy. The similarity is remarkable.

The primary difference between DOP Balsamic and our condimento, is that out of the gate our Condimento is inoculated with a very small amount of premium quality, barrel aged Italian wine vinegar. The barrel aged wine vinegar introduces the natural acetic bacteria and yeast and begins the process from cooked grape must to “condimento”. It is then aged using the Solera method which dictates that it be placed in a succession of different types of very old, fired wood barrels, each of which previously contained residual amounts of older balsamic dating back as far as 18 years and in some cases 25 years. It’s topped off as it moves from barrel to barrel, based on the Solera method, with younger, wood fire cooked grape must as it naturally evaporates. For this reason, no product except actual DOP certified balsamic in licensed 100 ml. bottles can make an actual age claim – ever!

As with DOP balsamic, our condimento’s very low acidity of 4% is a function of the grape must being naturally cooked down, condensed, caramelized and aged without the addition of much else, unlike so many “balsamic-like” products on the market which are not from Modena and are comprised almost wholly of poor quality wine or distilled vinegar, thickeners, color and sweeteners. The density and complexity of our condimento are a testament to the fact that it is made in Modena in the Solera method from high quality grape must, cooked down over an open wood fire. Its very high level of dried extract solids is close to if not identical to that of DOP Traditional Balsamic sold exclusively in 100ml. bottles.